Site Search

Contact: Mr Yuan

Mobile:18822809251

Tel:+86-0755-2314670

QQ:2144782477

e-mail:szhsxpcb@126.com

Address:No. 1 Xinhe Avenue, 8th Industrial Zone, Gonghe Community, Shajing Sub-District Office, Bao'an District, Shenzhen .

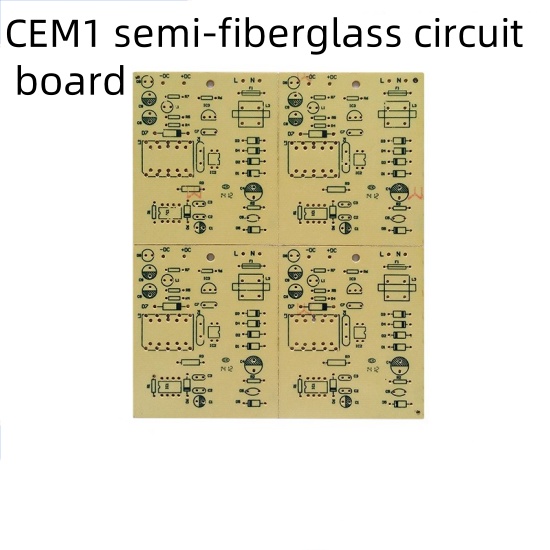

CEM-1

CEM-1 is an epoxy paper-core glass cloth composite base laminate with a flame retardant rating of 94 VO.

Product Characteristics:

Excellent heat resistance and moisture resistance.

Good punchability, with an optimal punching temperature range of 45℃~70℃.

Applications:

Displays, video recorders, power supply substrates, industrial instruments, digital recorders, etc.

Common Specifications:

Base thickness: 1.0mm, 1.2mm, 1.5mm, 1.6mm.

Copper foil thickness: 35um, 70um.

Substrate color: White, yellow.

CTI: 175V, 600V.

Sheet size: 9271230mm, 10201030mm, 1044*1245mm.

Structural Features:

CEM-1 is made by impregnating paper with epoxy resin, then laminating a layer of glass fiber cloth on both sides, and finally bonding it with copper foil through hot pressing. Therefore, it has two additional layers of glass fiber cloth compared to FR-3, resulting in superior overall performance.

Performance Advantages:

Mechanical strength, moisture resistance, flatness, heat resistance, electrical properties, etc., are all superior to paper-based CCLs.

It can be used to manufacture PCBs with high frequency characteristics requirements, such as TV tuners, power switches, ultrasonic equipment, computer power supplies, and keyboards.

CEM-3

CEM-3 is a composite copper-clad laminate with performance levels and pricing between those of CEM-1 and FR-4. The following are its detailed parameters:

Structural Features:

It uses epoxy resin glass fiber cloth-based adhesive sheets as the surface material and epoxy resin glass fiber paper-based adhesive sheets as the core material, which are then covered with copper foil on one or both sides and hot-pressed.

Performance Parameters:

Glass transition temperature, solder resistance, peel strength, water absorption, electrical breakdown, insulation resistance, UL ratings, etc., all meet FR-4 standards.

Bending strength is lower than that of FR-4, and thermal expansion is greater than that of FR-4.

Production Process:

Similar to FR-4, the glass mat can be glued using either vertical or horizontal gluing methods.

The epoxy resin system used is the same as that for FR-4, but can be modified to improve performance, often requiring the addition of a certain amount of filler.

The pressing pressure is generally half that of FR-4.

To accommodate different thickness requirements, glass mats of different weights can be used, with common weights being 50g, 75g, and 105g.

Price:

Affordable pricing, cheaper than FR-4.

Suitable for the production of simple double-sided boards.

188-2280-9251

Website:www.huashing-pcb.com

Address:No. 1 Xinhe Avenue, 8th Industrial Zone, Gonghe Community, Shajing Sub-District Office, Bao'an District, Shenzhen .

Please submit your request and we will call you right back