Site Search

Contact: Mr Yuan

Mobile:18822809251

Tel:+86-0755-2314670

QQ:2144782477

e-mail:szhsxpcb@126.com

Address:No. 1 Xinhe Avenue, 8th Industrial Zone, Gonghe Community, Shajing Sub-District Office, Bao'an District, Shenzhen .

Core Parameters

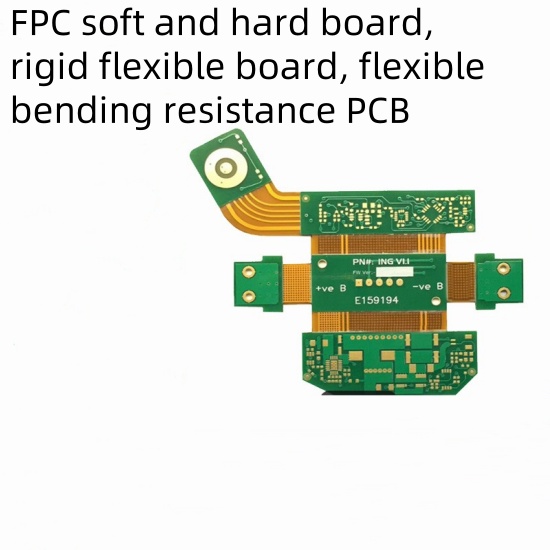

Material Composition:

Rigid Section: Typically employs glass fiber-reinforced epoxy resin (FR-4) or high-performance ceramic materials, providing stable mechanical support.

Flexible Section: Utilizes polyimide (PI) or polyester (PET) films, endowing the circuit board with excellent flexibility and temperature resistance.

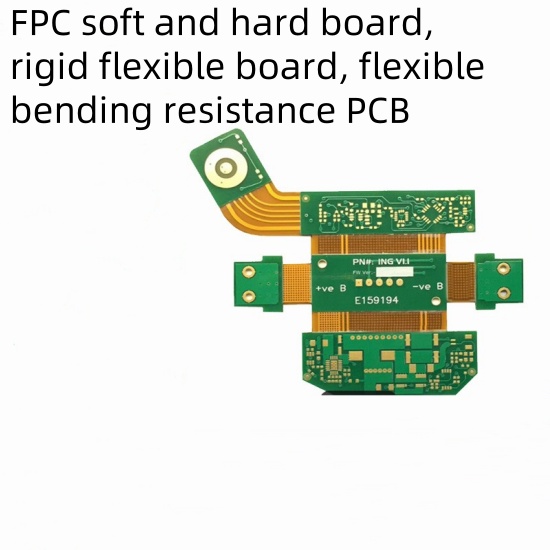

Size and Shape:

Size: Customized according to application requirements, with adjustable length, width, and thickness.

Shape: Supports complex 3D shape designs, such as folding and curling, to accommodate compact space layouts.

Layer Count and Structure:

Layer Count: Ranges from single-layer to multi-layer, determined by signal transmission needs.

Structure: Rigid and flexible layers are combined through precise lamination processes, ensuring a balance between electrical performance and mechanical strength.

Copper Thickness and Line Width/Spacing:

Copper Thickness: Conventionally ranges from 1/2 ounce to 4 ounces (approximately 18µm to 175µm), adjusted based on current load and heat dissipation requirements.

Line Width/Spacing: Minimum line width/spacing can reach 50/50µm or smaller, supporting high-density interconnection.

Thickness:

Total Thickness: Varies according to design needs, typically between 0.2mm and 2.0mm.

Flexible Section Thickness: Usually 0.1mm to 0.2mm, can be thickened to 0.4mm to meet specific requirements.

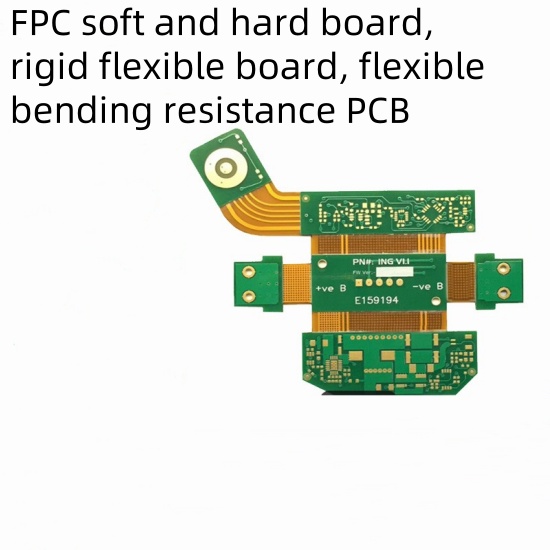

Surface finished:

Electroplating: Options include immersion gold, tin plating, OSP (Organic Solderability Preservative), etc., enhancing soldering reliability and corrosion resistance.

Solder Mask: Employs green or other colored inks to protect the circuit from environmental erosion.

Thermal Management and Electrical Performance:

Thermal Conductivity: Depends on material selection, providing effective heat dissipation paths.

Impedance Control: Supports differential pairs and high-speed signal transmission, ensuring signal integrity.

Reliability Testing:

Bending Cycle Test: Verifies the durability of the flexible section.

Thermal Shock Test: Assesses material stability under varying temperatures.

Electrical Performance Test: Includes insulation resistance, dielectric strength, etc., ensuring the electrical safety of the circuit board.

Application Areas

Rigid-Flex PCB is widely used in fields requiring high integration, flexible layout, and reliable performance, such as wearable devices, smartphones, medical equipment, aerospace electronics, automotive control systems, etc.

Customization Services

Comprehensive customization services are provided, including design consultation, material selection, prototype fabrication, mass production, and post-sales technical support, ensuring fulfillment of customers' specific needs.

188-2280-9251

Website:www.huashing-pcb.com

Address:No. 1 Xinhe Avenue, 8th Industrial Zone, Gonghe Community, Shajing Sub-District Office, Bao'an District, Shenzhen .

Please submit your request and we will call you right back