Site Search

Contact: Mr Yuan

Mobile:18822809251

Tel:+86-0755-2314670

QQ:2144782477

e-mail:szhsxpcb@126.com

Address:No. 1 Xinhe Avenue, 8th Industrial Zone, Gonghe Community, Shajing Sub-District Office, Bao'an District, Shenzhen .

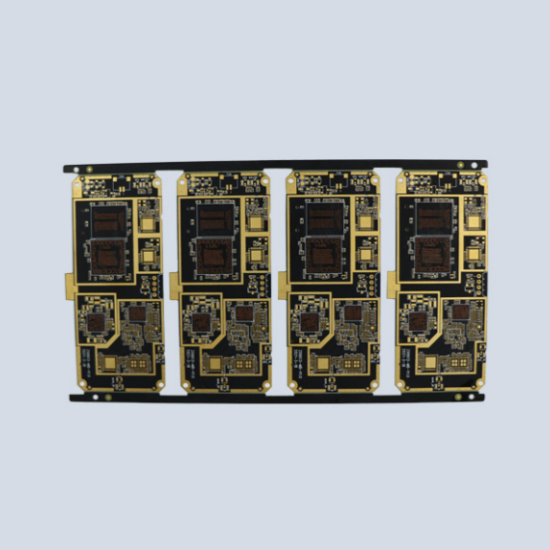

Methods for Quickly Detecting Faults in PCB Multilayer Circuit Boards.

Making an FCB multilayer board is not as simple as following the process to complete the board, drilling holes, and mounting components. The production of PCB multilayer circuit boards is not difficult, but the challenging part lies in troubleshooting after production. Whether for hobbyists or industry engineers, encountering issues during PCB circuit board debugging can be quite a headache, much like a programmer encountering a bug. Some people have a keen interest in debugging PCB circuit boards, just as programmers enjoy solving bugs.

There are many common issues with PCB circuit boards, including circuit board design flaws, damaged electronic components, short circuits, component quality issues, and broken traces on the PCB circuit board.

Most common faults in PCB circuit boards are related to components, such as capacitors, resistors, inductors, diodes, transistors, MOSFETs, integrated chips, and crystals that are visibly damaged. A relatively straightforward method to diagnose these component faults is through visual inspection. Electronic components with obvious damage will have noticeable burn marks on their surfaces. For such faults, replacing the problematic components with new ones can resolve the issue.

However, not all damaged electronic components can be observed with the naked eye. In some cases, damage to components like resistors, capacitors, and diodes may not be visible from the outside and requires the use of specialized inspection tools for repair. Common inspection tools include multimeters and capacitance meters. If the voltage or current of a certain electronic component is outside the normal range during testing, it indicates that there is an issue with that component or the preceding one. Simply replace it and check if the problem is resolved.

If a component is faulty, it can be detected through either visual inspection or instrument testing. However, sometimes when assembling components on a PCB board, we may encounter situations where no issues are detected, but the circuit board still fails to function properly. Many beginners are at a loss when faced with this problem and can only resort to making a new board or buying one. In fact, in such cases, it is often due to performance instability caused by the coordination issues among various components during the installation process.

When this happens, instruments can no longer be of help. One can try to determine the possible range of the fault based on current and voltage readings and narrow it down as much as possible. Experienced engineers may quickly identify the fault area, but they cannot be certain which specific component is faulty. The only solution is to try replacing suspicious components until the problematic one is found. Last year, when my laptop's motherboard got wet, the technician encountered a situation where the fault could not be detected during the repair process. Three components were replaced in the process: the power supply chip, a diode, and the USB charging component (the blue port on the laptop that can charge devices when the laptop is off). Ultimately, it was determined through waves of testing and replacing suspicious chips that a component next to the southbridge chip was short-circuited.

The issues mentioned above mainly pertain to electronic components. Of course, since the PCB circuit board serves as the foundation for components, circuit board faults can also exist. A simple example is the soldering areas. Due to manufacturing processes, broken traces may occur during the PCB etching process. In such cases, if it is not possible to repair the trace, it can only be resolved by using a thin copper wire to create a jumper.

When PCB circuit board faults are not visibly damaged, they can be quite troublesome to diagnose. During the troubleshooting process, there is a sense of focus, and once the problem is identified, there is a sense of accomplishment. Programmers who solve bugs feel the same way. I often enjoy troubleshooting difficult-to-repair boards. Perhaps this is the joy of being an HDI multilayer board engineer.

188-2280-9251

Website:www.huashing-pcb.com

Address:No. 1 Xinhe Avenue, 8th Industrial Zone, Gonghe Community, Shajing Sub-District Office, Bao'an District, Shenzhen .