Site Search

Contact: Mr Yuan

Mobile:18822809251

Tel:+86-0755-2314670

QQ:2144782477

e-mail:szhsxpcb@126.com

Address:No. 1 Xinhe Avenue, 8th Industrial Zone, Gonghe Community, Shajing Sub-District Office, Bao'an District, Shenzhen .

Polyimide Vs. FR4 – which is better?

Before comparing the materials, let’s briefly discuss what FR4 is.

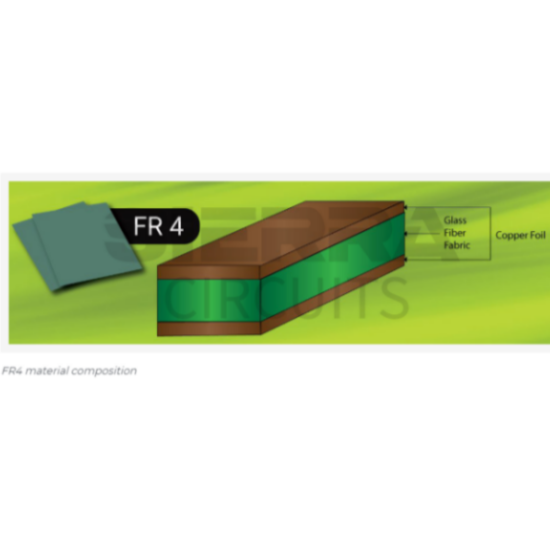

FR4 stands for flame retardant, level 4. This is a substrate that comprises an epoxy resin and glass weave. It is a popular choice as the material has good mechanical and electrical properties and is also cost-efficient. The primary difference between polyimide and FR4 is flexibility.

Additionally, FR4 can be fabricated with a standard manufacturing process, whereas PI needs a higher temperature. The choice of substrate depends on the circuit and application requirements.

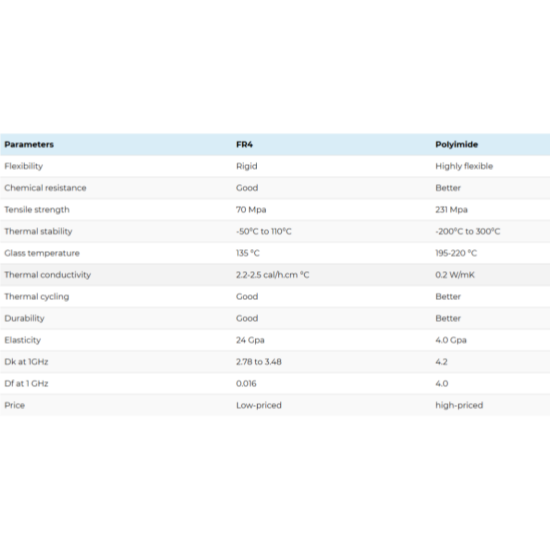

The below table provides a detailed difference between polyimide and FR4 PCB materials. Knowing these differences will help you make the right decision.

Polyimide Vs. Polyamide – what is the difference?

Both of them are thermosetting plastics that are heat resistant. However, the significant difference is in their chemical structure. Polyimide has an imide (-CO-N-OC-) group construction in resin form. Hence, we use it in board applications. On the other hand, polyamides have an amide (-CONH-) linkage, which is mostly in thread forms such as nylon. This is not suitable for circuit board construction. However, both these materials have outstanding electrical and physical characteristics.

Different kinds of polyimide PCB materials

Polyimide board substrates can be classified into different categories depending on the structure and the additives included.

Categorization based on the main chain composition

• Aromatic polyimide is a derivative of aromatic dianhydride and diamine, which have an open chain structure.

• Aliphatic is a combination of aliphatic dianhydride and diamine. These have both open and closed chains of compounds.

• Semi-aromatic has a part of aromatics (dianhydride or diamine) and a part of aliphatic.

Classification based on the inclusion of the additive

With no fillers

As the name suggests, this PI version does not contain additives such as brominated flame retardant. These are the pure and oldest kind of polyimide available and fall under the second-generation material. They are still popular as they are more flexible, strong, and thermally stable than other types of PI.

With flame retardants

These are updated versions of the 2nd generation with an added additive of flame retardants. This makes the polyimide PCB material more resistant to accidental fire.

The inclusion of an additive lowers the time and temperature needed for producing the substrate. Hence, bulk production is possible. On the contrary, it reduces its thermal stability.

Many tests and regulations exist to check for the fire safety of a substrate. For instance, Underwriters Laboratory has set UL-94 flammability standards that categorize plastics into classes like V0, V1, V2, HB, etc. As an example, the DuPont™ Kapton HN polyimide falls under the UL-94 class V0.

With flow restrictors

The low-flow polyimides are built with flow restrictors and resin. Hence, they are not as flexible as other versions, and this stiffness becomes useful to withstand harsh environments. Choose this type of PI laminate if your design calls for higher durability materials.

Filled type polyimide

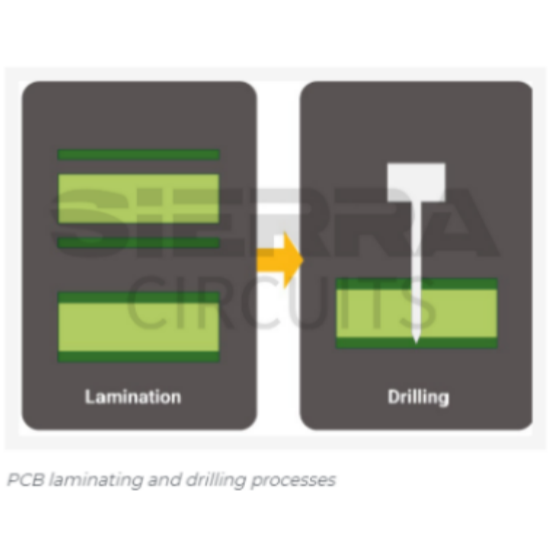

This PI is cured with various filler materials to avoid cracks or breakage in the resin during the lamination and drilling processes.

All the above substrates with additives fall under the 3rd generation polyimide category. In addition, 4th generation materials are expected to have improved adhesion properties and overall stability.

Polyimide PCB material applications

The versatility of PI makes it desirable for a wide range of applications in both domestic and advanced usage. Consumer-based applications With a constant demand for advanced, compact, and lightweight handheld devices, polyimide flex boards have enormous potential for consumer applications. Examples include computers, laptops, tablets, smartphones, video game consoles, and televisions. The material’s durability and thermal stability enable the gadgets to withstand heat and stress generated due to prolonged usage.

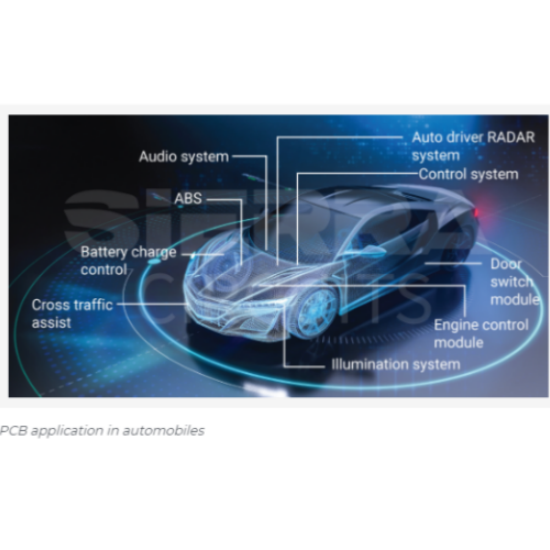

Polyimide circuit boards in the automotive industry

Cars and automobiles are built with many electronic devices such as engine control systems, audio systems, antilock braking systems (ABS), etc. These features ensure proper control and operation of the vehicle. Circuit boards in automobiles must withstand vibrations, temperature variation, and wear and tear.

Therefore, the materials used in these electronics should be robust. Polyimide flex PCBs have excellent mechanical strength and can bend to fit into irregular spaces. Hence, they are a popular choice for this application.

For more, see automotive PCB design guidelines.

Medical diagnostics and treatment equipment

The medical industry has increasingly relied on electronics for diagnostics and treatment. Equipment such as magnetic resonance imaging, ultrasound technology, and other advanced applications are aiding healthcare staff.

Circuit boards in medical devices can be exposed to contamination and temperature variations. Therefore, choosing a chemically resistant substrate is a prerequisite. To learn about standards, read MedTech PCB design considerations with IPC and Ul standards.

In cases like hearing aids and implants, the circuit needs to be compact and lightweight. Many prefer polyamide flex PCBs for these applications.

Military and aerospace applications

In military and aerospace applications, the boards have to operate in extreme environments. Therefore, the mil-grade laminate should have a high glass transition temperature (Tg). It is also ideal to have substrate materials with a low CTE and reduced losses.

A few applications that require advanced circuit boards are power distribution systems, digitized signal processing, flight instrumentation, communication, and navigation systems.

Even though they are not invincible, polyimide circuit board materials exhibit durability and thermal stability, which makes them the right choice for the military and aerospace industries. As this substrate can become brittle with heavy copper, choose a filled PI that is resistant to cracks. All these advanced applications must comply with IPC standards and other regulations.

Prefer polyimide PCB material if you are working on flex designs that require higher thermal stability. These materials are tailored for operations in harsh environments. It can also be a good alternative for FR4 when there are no cost constraints. If you need anything more on PCB material selection, please comment below. We will be happy to help you out.

188-2280-9251

Website:www.huashing-pcb.com

Address:No. 1 Xinhe Avenue, 8th Industrial Zone, Gonghe Community, Shajing Sub-District Office, Bao'an District, Shenzhen .